FS conventional products are used for cooling and heating in HVAC; cooling and heating in industrial processes; oil coolers; evaporators, condensers and economizers in the refrigeration industry; and economizers in air-source heat pump water heaters. When applied to phase change heat transfer (evaporator, condenser and economizer) or strict requirements for pressure drop, FEKS conventional products can get higher heat transfer efficieny

FS conventional products are used for cooling and heating in HVAC; cooling and heating in industrial processes; oil coolers; evaporators, condensers and economizers in the refrigeration industry; and economizers in air-source heat pump water heaters. When applied to phase change heat transfer (evaporator, condenser and economizer) or strict requirements for pressure drop, FEKS conventional products can get higher heat transfer efficieny

FS conventional products are used for cooling and heating in HVAC; cooling and heating in industrial processes; oil coolers; evaporators, condensers and economizers in the refrigeration industry; and economizers in air-source heat pump water heaters. When applied to phase change heat transfer (evaporator, condenser and economizer) or strict requirements for pressure drop, FEKS conventional products can get higher heat transfer efficieny

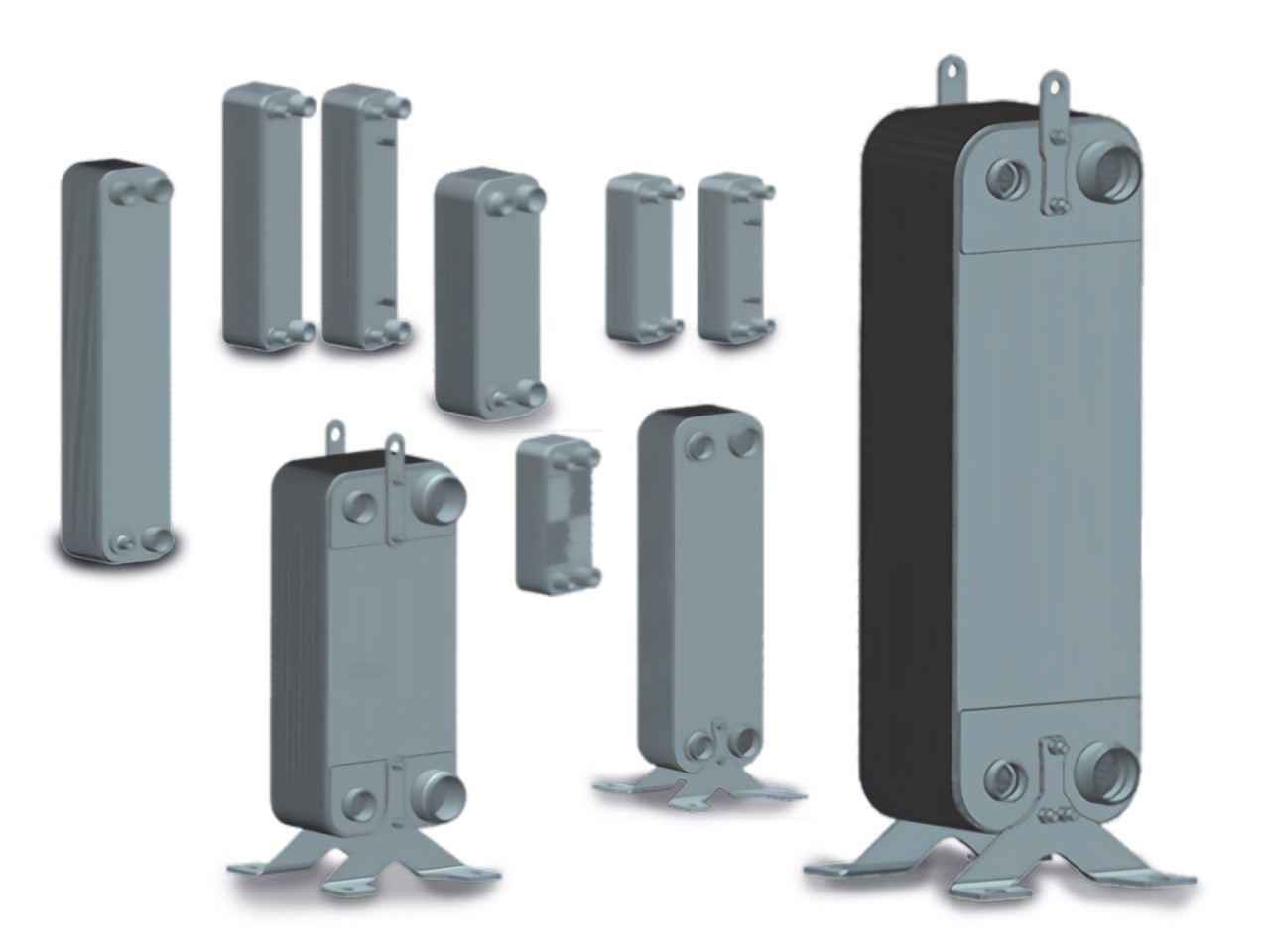

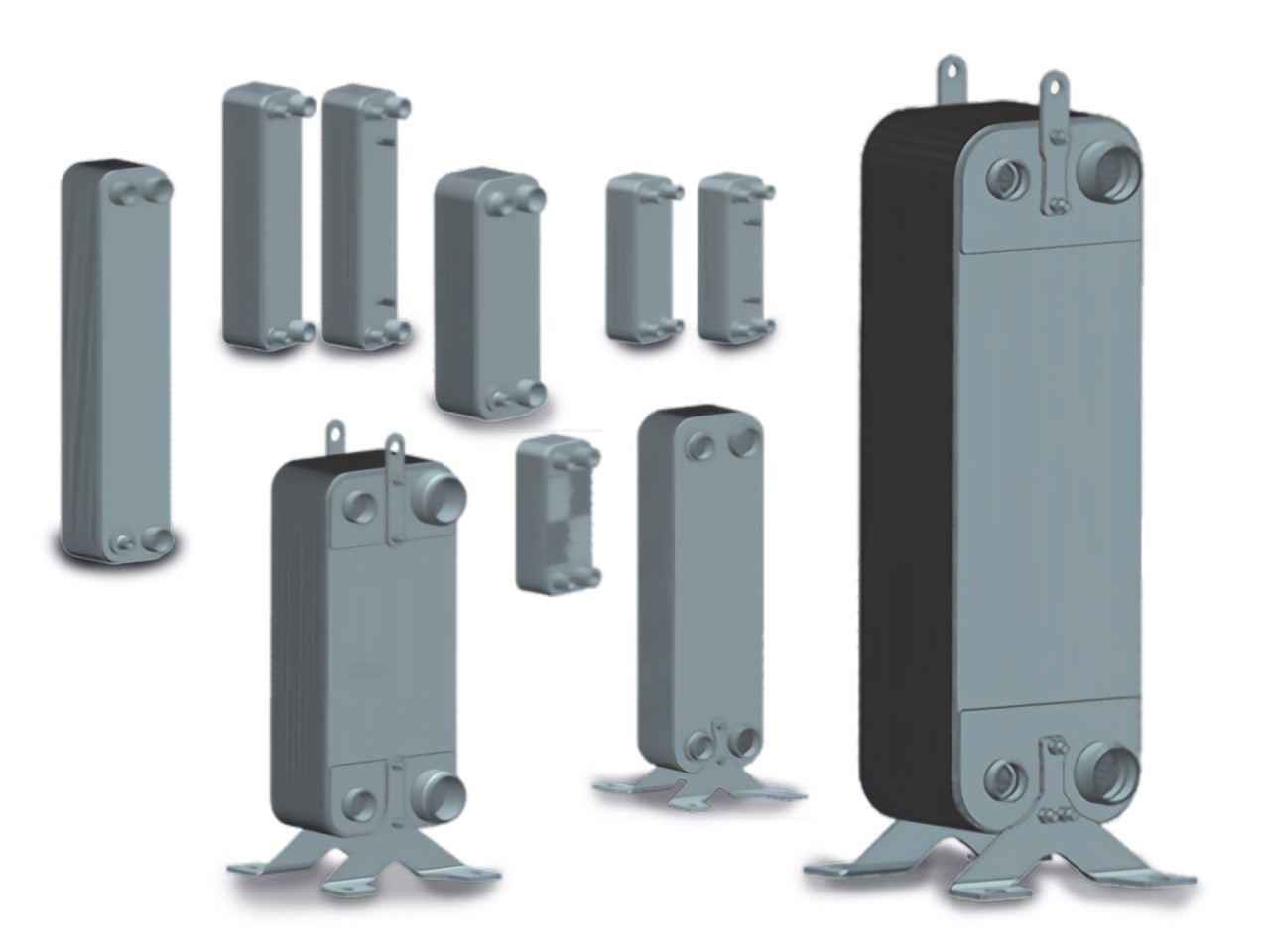

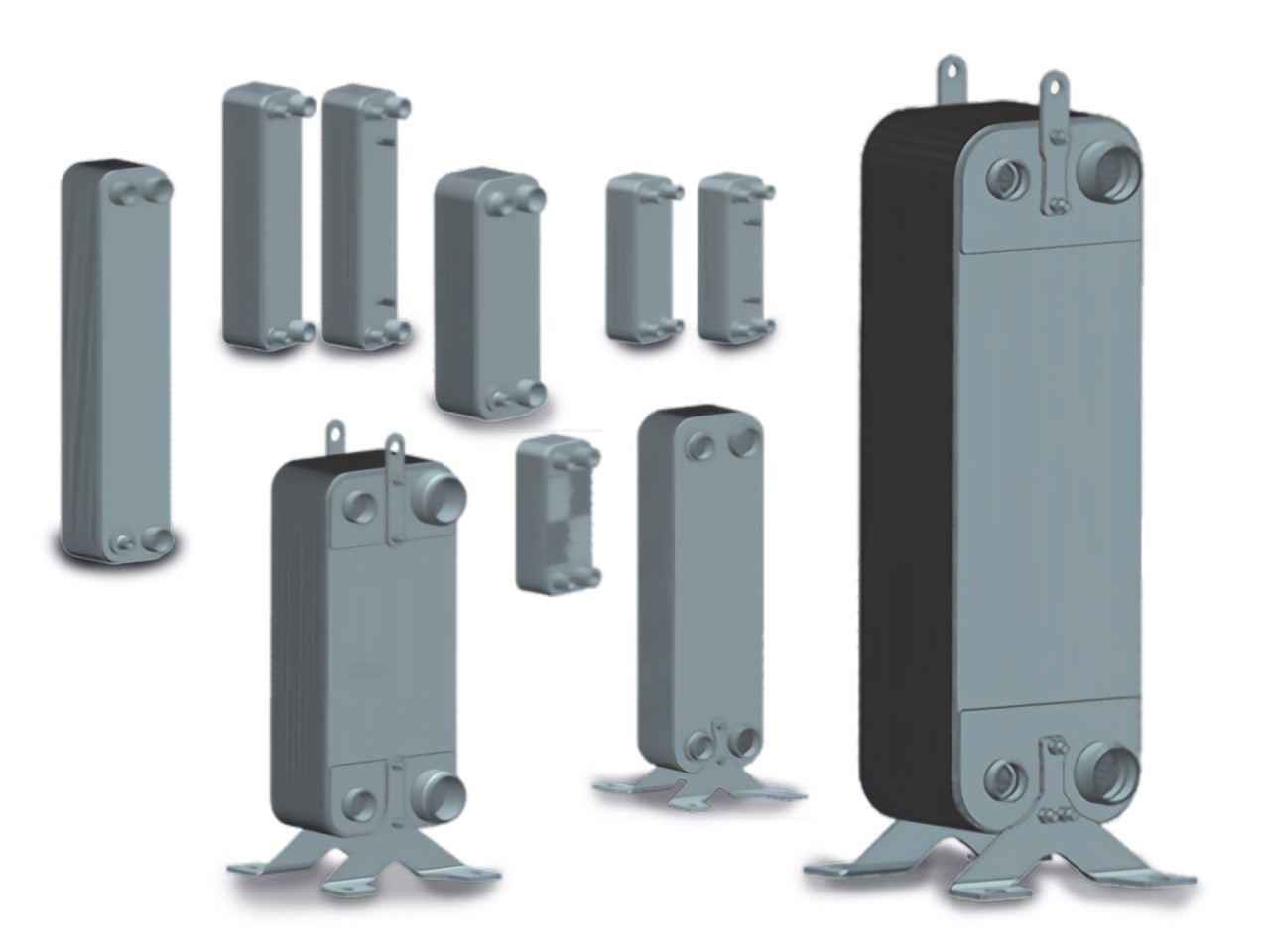

Products description

Products description